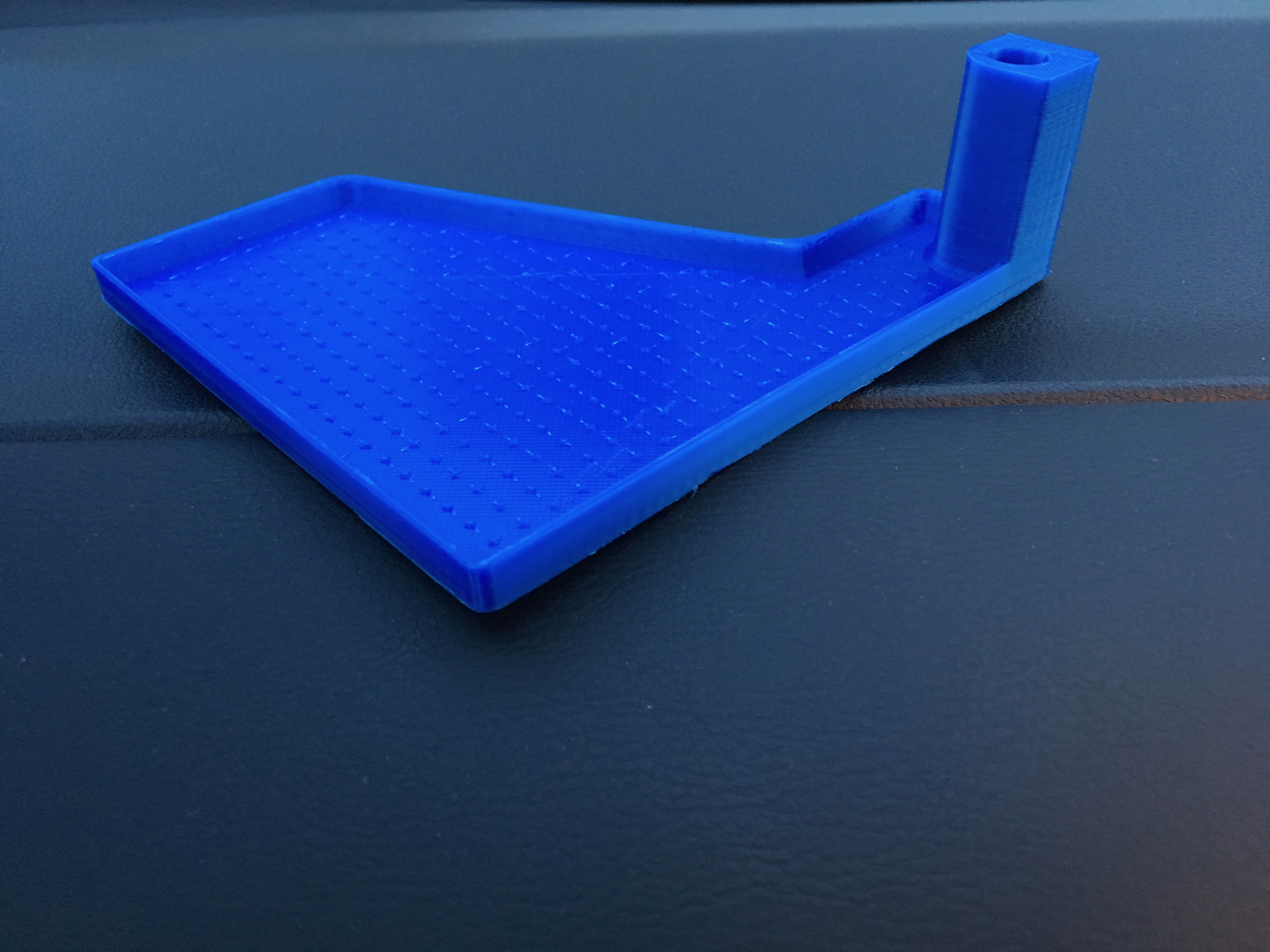

Car centre-console tray

I made a flexible pen holder and noise dampening mat for the centre console of my car because the bin under the arm-rest has a plasticy bottom and there’s nowhere to store a pen. Unfortunately, the bin is not long or wide enough to allow my car pen to sit inside it comfortably, so it has to stand up vertically. This means that it rattles whenever I drive round a corner or over a bump.

I’m used to having somewhere to store things like pens in a car and my last two have had somewhere to hold a pen without it rattling. I also wanted to store an OBD2 dongle in the centre console without it rattling. Since there’s nowhere to put these things, I realised that the only way to solve this issue was to make one myself.

I’m used to having somewhere to store things like pens in a car and my last two have had somewhere to hold a pen without it rattling. I also wanted to store an OBD2 dongle in the centre console without it rattling. Since there’s nowhere to put these things, I realised that the only way to solve this issue was to make one myself.

Templating

I made a template with paper by carefully cutting out a piece to match the bottom of the bin that I wanted to fit to. Then I measured this part to get the dimensions. I sketched the shape in Fusion360, then used my 3D printer to make an outline of the shape to confirm that it fitted.

Once I was convinced that I’d copied the shape accurately, I designed the part to have an insert for my pen and a wide base with dimples on it to hold other stuff that might go into the storage bin.

Manufacture

I printed the part in flexible TPE, which is a bit of a challenge since it’s a rather temperamental material. You need to make sure that the nozzle is at exactly the right height from the bed and then make sure that the print speed is low so that the material doesn’t stretch in the nozzle or feeder. The trick on my printer is to make sure that the bed is levelled once the whole machine has warmed up since it all moves around whilst heating up. PLA will accommodate this, but TPE will not.

You can download the STL file of this part on Thingiverse.